Your cart is currently empty!

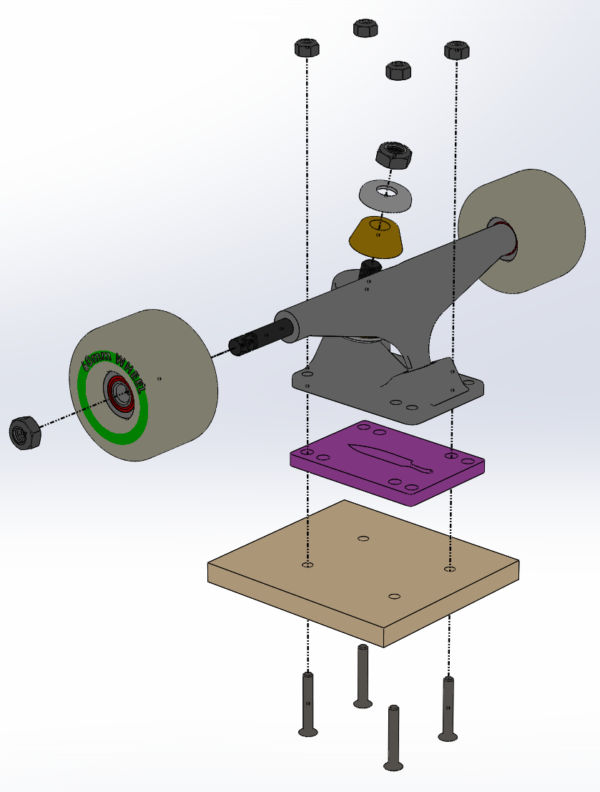

Skateboard Riser & Hardware Guide

Skateboard risers, or riser pads, are spaces fitted between the trucks and deck of a skateboard. They function to separate the deck and truck to prevent wheel bite. Which can be described as, the sudden unforgiving moment when your wheel decides to quit on you, usually right before you faceplant the concrete.

A secondary function of risers, depending on your skating style, is reducing stress cracks, which can prolong the life of your deck. Deciding whether you need risers boils down to your wheel size, and how loose your trucks are. Your odds of wheel bite increases with wheel size, and loose trucks add to these odds.

Table of Contents

Skateboard Risers and Clearance

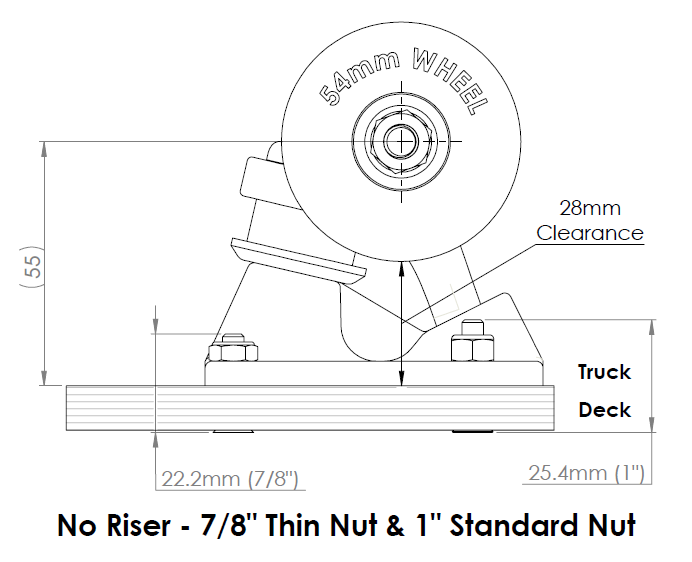

Below is a general guide for Riser Height and Hardware Length, based on Wheel Size. Given there is no hard and fast rule, results may vary.

| WHEEL SIZE | RISER HEIGHT [“] | RISER HEIGHT [mm] | HARDWARE LENGTH [“] |

| 49 – 54 mm | NO RISER | NO RISER | 7/8″ – 1″ |

| 55 – 57 mm | 1/8″ | 3 mm | 1″ – 1 1/8″ |

| 58 – 64 mm | 1/8″ – 1/4″ | 3 – 6 mm | 1 1/4″ |

| 65 – 67 mm | 1/4″ – 1/2″ | 6 – 13 mm | 1 1/4″ – 1 1/2″ |

| +68 mm | 1/2″ – 5/8″ | 13 – 16 mm | 1 1/2″ |

With No Risers installed and 54mm wheels, assuming we’re riding Indy Stage Elevens with a height of 55mm, we start with a minimum clearance of 28mm. This clearance distance is a minimum because its measured at the baseplate in the diagrams. Therefore, this value will increase depending on how much concave your deck has, and if wheel wells are present.

Going up to 57mm wheels with 3mm (1/8″) risers we maintain a similar clearance of 30mm. This trend holds for 60mm wheels with 6mm (1/4″) risers. Note that the clearance will decrease by the change in the wheel’s radius, not its diameter. Remember, the radius is half the diameter!

With 66mm wheels installed and 10mm riser pads we increase the clearance to 32mm. This shows we could get away with only 6mm risers, if we’re happy with a clearance of 28mm. The same clearance as 54mm wheels and no risers. Swapping to 69mm wheels and 13mm (1/2″) risers our clearance goes up to 34mm.

By installing 16mm (5/8″) and 19mm (3/4″) risers with 69mm and 73mm wheels the clearance increases again. This shows that these risers will provided a conservative amount of clearance. Which is not a bad thing because with BIG wheels, comes BIG speed!

Riser Pads for Minimum Clearance

| WHEEL SIZE | RISER HEIGHT [“] | RISER HEIGHT [mm] | HARDWARE LENGTH [“] | CLEARANCE [mm] |

| 54 mm | NO RISER | NO RISER | 1″ | 28 |

| 57 mm | 1/8″ | 3 mm | 1 1/8″ | 30 |

| 66 mm | 1/4″ | 6 mm | 1 1/4″ | 28 |

| 69 mm | 3/8″ | 10 mm | 1 1/2″ | 31 |

| 73 mm | 1/2″ | 13 mm | 1 1/2″ | 32 |

Following the general table we can produce some conservative clearance values for our wheel size. Boiling that table down and aiming for minimum clearance gives us the table above. Having selected our wheel size, we can increase our riser height to improve our clearance. Last thing we’ll have to remember is that our hardware length is determined by our riser height.

If you’ve recently bought new wheels and your clearnace needs an uplift, head to the Store to grab some risers.

Hardware Guide

Typical hardware found on a skateboard consists of kingpins, nuts, and deck bolts. Personally I haven’t crossed paths with inverted kingpins but going off the Indy website they appear to be tartgeted towards “technical” street skating. So its no surprise they haven’t appeared on my radar.

Starting with the nuts, there are three different sizes. The threads are Imperial and designated within the Unified National Fine (UNF) standard. Key take-aways from this are, use your imperial tools, and measure them using the inches side of your ruler. Being UNF there are not any metric threads “close” to these sizes. So if your choosing to test you strength by winding metric nuts onto these threads, you better have had your Wheet Bix.

| Nut Location | Thread Size | Type |

| Kingpin | 3/8″ – 24 UNF | Nyloc Nut |

| Axle | 5/32″ – 24 UNF | Nyloc Nut |

| Deck Bolts | 10 (3/16″) – 32 UNF | Nyloc Nut |

Two other key hardware parameters are material and grade. Where the material of the hardware will impact its grade, with alloy steel being most common and offering the most strength. But it is the grade of the hardware that is more commoningly used when ordering and specifying hardware strength.

The chart below was summarised from boltandnut and it compares grades and materials of hardware. Grade 8 is most common for skateboard hardware, especially for deck bolts.

Alloy steel populates most of the chart, and stainless steel hardware has a comparable strength to Grade 5 alloy steel. I would consider Grade 5 the lowest grade suitable for skateboard hardware, if your in a pinch.

Tooling

At some past point in time the T-Tool came along and simplified finding the right tooling. While the T-Tool can deal with all the hardware, standard tools will still work. So there is nothing stopping you from fusing together your own DIY T-Tool!

Hardware and Tool Size

| HARDWARE | TOOL SIZE |

| KINGPIN NUT | 9/16″ |

| AXLE NUT | 1/2″ |

| DECK NUT | 3/8″ |

| DECK BOLT (HEX HEAD) | 1/8″ |

| DECK BOLT (PHILLIP HEAD) | No. 2 |

by