Your cart is currently empty!

Capabilities

Current capabilities consist of four 3D printers, a spray booth and all the hand tools required to build the large 500mm cubed 3D printer. I have owned 3D printers for over 5 years and have operated large format 3D printers with build volumes larger than 1 meter cubed. I got into building and painting plastic models 2 years ago after moving on from making remote control Lego kits. These adventures and others are captured here.

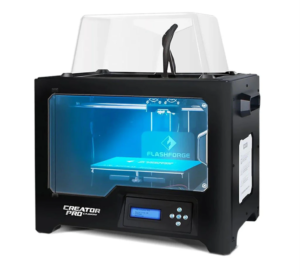

Flash Forge Creator Pro

Dual extruder printer with a heated bed and an enclosure. Hot end has been upgrade to a Micro Swiss All Metal Hot End allowing higher printing temperatures required for engineering materials such as Nylon.

Build Volume: 230 x 150 x 150 mm

Materials: ABS, ASA, NYLON, PLA, PETG

Nozzle Sizes: 0.2mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm

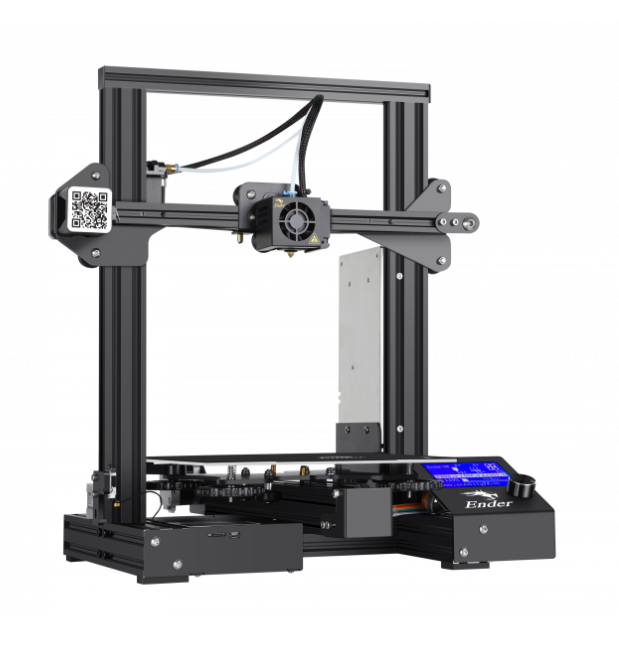

Ender 3 Pro

Bowden Extruder 3D Printer with PEI or Glass build surfaces. Bowden tubes have been upgraded to Capricorn PTFE Bowen Tubes.

Build Volume: 220 x 220 x 250 mm

Materials: PLA, PETG

Nozzle Sizes: 0.4mm, 0.6mm, 0.8mm, 1.0mm

Modified Ender 3 – A.K.A Marvin 5

Modified Ender 3 Pro. Modifications include, dual Z Axis, ABL Probe and a Microswiss NG Extruder.

This Ender 3 is upgraded to print flexible filaments.

Build Volume: 220 x 220 x 250 mm

Materials: PLA, PETG, TPU

Nozzle Sizes: 0.4mm, 0.6mm, 0.8mm, 1.0mm

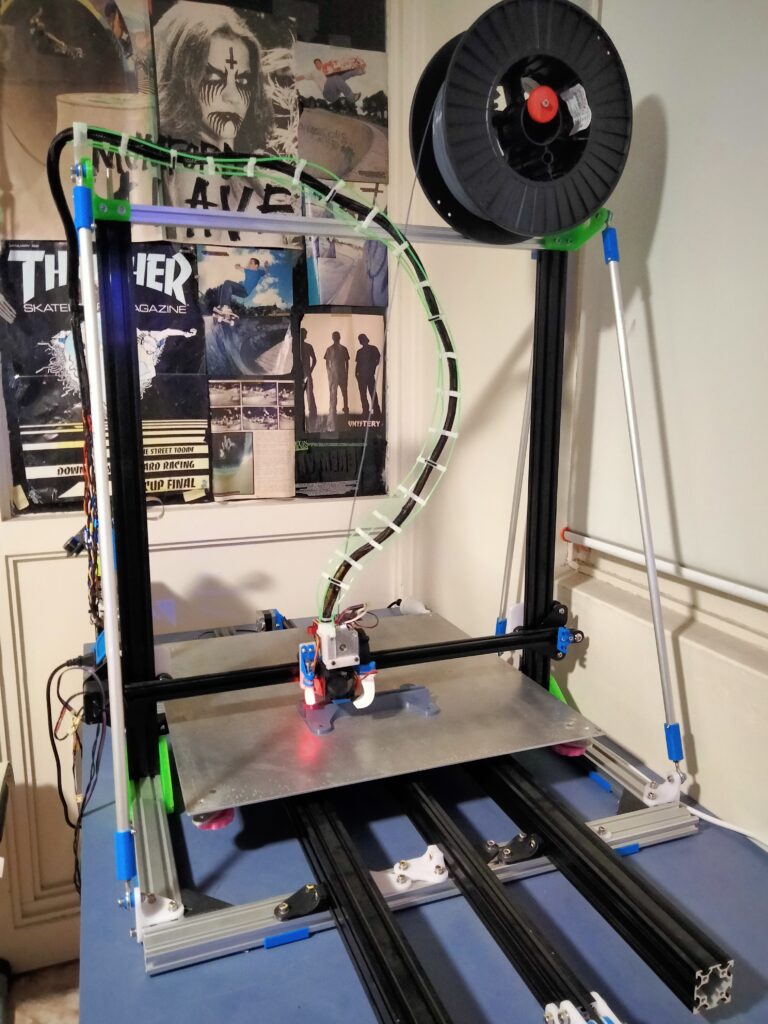

500 Cubed (A LARGE Ender 3)

A printer of my own creation that swallowed a whole Ender 3. Dual Z Axis, ABL Probe and a 500 x 500 x 500 mm build volume. Upgrading to a heated bed and making an enclosure is in the works. Currently running with a 0.8mm Nozzle producing large and sturdy parts for printer upgrades, modelling and bike repairs.

Build Volume: 500 x 500 x 500 mm

Materials: PLA, (Anything that works with a room temperature bed)

Nozzle Sizes: 0.4mm, 0.6mm, 0.8mm, 1.0mm